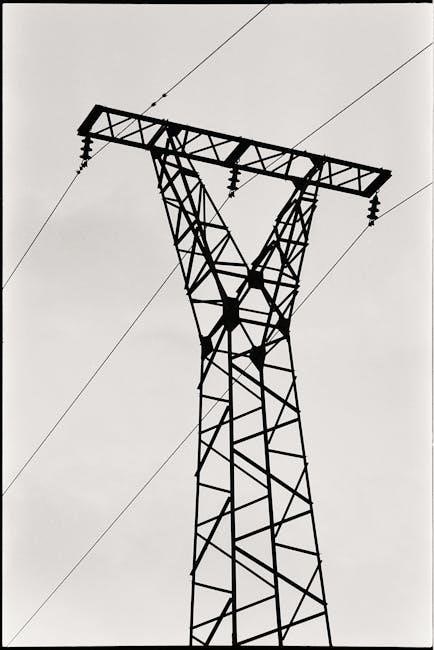

Manual power poles are essential structures in utility distribution, providing reliable support for electrical and communication lines․ Made from durable materials like wood, concrete, or steel, these poles ensure efficient energy transmission and connectivity, playing a crucial role in modern infrastructure․

1․1 Definition and Purpose

A manual power pole is a tall, sturdy structure designed to support electrical power lines, communication cables, and associated equipment․ Its primary purpose is to elevate conductors safely above ground, ensuring reliable energy distribution and connectivity․ These poles are typically made of durable materials like wood, concrete, or steel, chosen for their strength and longevity․ They play a critical role in utility systems, enabling the transmission of electricity and telecommunication signals over long distances while maintaining public safety and minimizing environmental impact․

1․2 Importance in Utility Distribution

Manual power poles are indispensable in utility distribution, serving as the backbone for electrical and communication networks․ They provide the necessary elevation for power lines and cables, ensuring safe and efficient energy transmission․ By preventing interference and damage from ground-level hazards, these poles enhance system reliability․ Their tall structure also allows for spanning long distances, making them vital for connecting remote areas and maintaining universal access to essential services, thus underpinning modern infrastructure and daily life․

Components of a Manual Power Pole

Manual power poles consist of a sturdy shaft, base, crossarms, insulators, and climbing hooks, designed to support and distribute power lines efficiently and safely․

2․1 Materials and Construction

Manual power poles are constructed from durable materials such as treated wood, steel, or concrete, ensuring longevity and strength․ Wooden poles are often cost-effective and lightweight, while steel and concrete poles offer enhanced durability and resistance to environmental factors․ The construction process involves treating the materials to withstand weather conditions and pests․ The poles are designed with a sturdy base and reinforced structures to support heavy loads, ensuring reliable power distribution and safety․

2․2 Key Features and Accessories

Manual power poles feature crossarms for mounting transformers and insulators, ensuring safe and efficient energy distribution․ Accessories include grounding systems, climbing hooks, and safety brackets to enhance functionality․ These components are designed to withstand environmental stresses and provide reliable service․ Additional features like anti-climbing spikes and vibration dampeners are often installed to prevent unauthorized access and reduce structural wear․ These elements collectively ensure the pole’s durability and performance in various conditions, making them critical for utility systems․

Installation and Maintenance

Manual power poles require proper site preparation and skilled labor for installation․ Regular inspections, cleaning, and timely repairs ensure longevity and reliability in power distribution systems․

3․1 Step-by-Step Installation Guide

Begin with site preparation, ensuring the area is clear and marked accurately․ Dig a foundation hole to the recommended depth and width․ Place the pole, ensuring it is straight and secure with temporary supports․ Backfill with soil and concrete around the base for stability․ Install crossarms, insulators, and conductors, following safety protocols․ Connect the lines carefully, ensuring proper tension and alignment․ Finally, test the installation for any defects or weaknesses before commissioning the pole for use․

3․2 Regular Maintenance Requirements

Regular maintenance for manual power poles involves inspecting for damage, cleaning surfaces, and ensuring all hardware is secure․ Check insulators and conductors for wear and tear, and replace them if necessary․ Trim vegetation around the base to prevent interference․ Test electrical connections and grounding systems annually․ Schedule routine inspections to identify potential issues early․ Document all maintenance activities to ensure compliance with safety standards and extend the pole’s lifespan․

Safety Considerations

Manual power poles require strict safety protocols, including proper grounding, use of PPE, and adherence to electrical safety standards to prevent accidents and ensure worker protection․

4․1 Personal Protective Equipment

When working with manual power poles, wearing appropriate Personal Protective Equipment (PPE) is crucial․ This includes hard hats, insulated gloves, safety glasses, and steel-toe boots to protect against electrical shocks, falling objects, and physical injuries․ Ensuring PPE is in good condition and properly worn minimizes risks during installation, maintenance, and repair tasks․ Additionally, using arc-rated clothing can provide further protection against electrical arc flashes, ensuring a safer working environment for utility personnel․

4․2 Emergency Procedures

In case of emergencies involving manual power poles, immediate action is essential to ensure safety․ If a pole is damaged or sparking, evacuate the area and contact utility professionals․ For electrical fires, use fire-resistant equipment and follow proper firefighting protocols․ Always disconnect power sources before attempting repairs․ Keep emergency contact numbers handy and ensure all personnel are trained in first aid and emergency response procedures․ Regular drills and updated safety manuals help prepare for unforeseen incidents, minimizing risks and ensuring prompt resolution․

Applications of Manual Power Poles

Manual power poles are widely used in electrical distribution and telecommunication systems․ They support power lines, ensuring reliable energy supply, and facilitate communication networks, enabling connectivity across various regions․

5․1 Electrical Distribution

Manual power poles are integral to electrical distribution systems, providing structural support for overhead power lines․ They ensure reliable energy transmission from substations to end-users, enabling consistent power supply․ These poles are strategically placed to minimize energy loss and maximize efficiency, making them a cornerstone of modern electrical infrastructure․ Their durability and versatility allow them to serve both urban and rural areas, ensuring electrification and connectivity for diverse communities․

5․2 Telecommunication Systems

Manual power poles play a vital role in telecommunication systems by supporting overhead cables, antennas, and other essential equipment․ They provide the necessary elevation for signal transmission, ensuring reliable connectivity for phone, internet, and data services․ Durable materials like steel or concrete are used to withstand environmental stresses, making these poles a cornerstone for modern communication networks․ Their installation in both urban and rural areas ensures widespread coverage, keeping communities connected and facilitating emergency services, education, and economic activities;

Advantages and Challenges

Manual power poles offer reliable support for electrical and communication lines, combining durability with cost-efficiency․ However, challenges include installation complexities and ongoing maintenance requirements․

6․1 Benefits of Manual Power Poles

Manual power poles are cost-effective and durable, providing reliable support for electrical and communication lines․ Their simplicity ensures easy installation and maintenance, while their versatility adapts to various environments․ Key benefits include long service life, resistance to harsh conditions, and minimal environmental impact, making them a practical choice for utility distribution systems․

6․2 Common Challenges and Solutions

Manual power poles face challenges like weather damage and material degradation․ Harsh weather conditions can weaken structures, while improper installation may lead to safety risks․ Solutions include using weather-resistant materials, regular inspections, and timely maintenance․ Additionally, training personnel in proper installation and repair techniques enhances reliability and safety, ensuring efficient operation of power distribution systems․

Best Practices for Manual Power Pole Maintenance

Regular inspections, timely repairs, and using durable materials are essential for maintaining manual power poles․ Proper tools and documentation ensure safety and efficiency․

7․1 Regular Inspections

Regular inspections of manual power poles are crucial to ensure reliability and safety․ Inspectors check for signs of wear, damage, or degradation, such as wood rot, corrosion, or loose connections․ Grounding systems and insulation are also evaluated to prevent electrical hazards․ Routine checks help identify potential issues before they escalate, reducing the risk of power outages or equipment failure․ Inspections should be documented and scheduled based on environmental conditions and usage patterns to maintain optimal functionality and extend the lifespan of the poles․

7․2 Troubleshooting Common Issues

Troubleshooting manual power poles involves identifying and resolving issues promptly․ Common problems include physical damage, electrical faults, or connection failures․ Inspect the pole for visible cracks, rust, or wear․ Check wiring and connectors for loose or corroded points․ Use diagnostic tools to test electrical continuity and insulation resistance․ Addressing issues early prevents further damage․ For complex problems, consult qualified technicians to ensure safe and effective repairs․ Regular maintenance can help mitigate these issues and extend the pole’s operational life․ Always prioritize safety during inspections and repairs․

Future Trends in Manual Power Pole Technology

Advancements include composite materials for durability and smart grid integration, enabling real-time monitoring and energy efficiency․ These innovations enhance reliability and adaptability in modern utility systems․

8․1 Innovations in Material Science

Recent advancements in material science have introduced high-performance composites and advanced polymers, enhancing durability and resistance to environmental factors․ These innovations reduce maintenance needs and extend the lifespan of manual power poles, ensuring long-term reliability in utility distribution․

8․2 Integration with Smart Grid Systems

Manual power poles are increasingly being integrated with smart grid systems, enabling real-time monitoring and control of energy distribution․ This integration leverages IoT devices and advanced sensors to optimize power flow, reduce energy losses, and improve reliability․ Smart grids allow for remote monitoring of pole performance, predictive maintenance, and faster response to outages․ This fusion enhances grid resilience, supports renewable energy integration, and ensures a more sustainable and efficient energy supply for future demands․

Manual power poles remain vital for reliable energy distribution, ensuring connectivity and supporting modern infrastructure․ Their evolution with smart technologies promises enhanced efficiency and sustainability for future energy needs․

9․1 Summary of Key Points

Manual power poles are vital structures in utility distribution, supporting electrical and communication lines․ Constructed from durable materials like wood, concrete, or steel, they ensure reliable energy transmission and connectivity․ Their design and installation are critical for safety and efficiency, with applications extending beyond electricity to telecommunications․ Regular maintenance and inspections are essential to prevent failures and ensure longevity․ Understanding their components, installation, and maintenance requirements helps maximize their performance and reliability in modern infrastructure․

9․2 Final Thoughts on Manual Power Poles

Manual power poles remain a cornerstone of modern infrastructure, providing essential support for electricity and communication lines․ Their durability and versatility ensure reliable service, while regular inspections and maintenance enhance their longevity․ As technology advances, manual power poles will continue to adapt, playing a vital role in utility distribution․ Their importance cannot be overstated, as they underpin the connectivity and energy needs of communities worldwide, ensuring consistent and efficient service for generations to come․